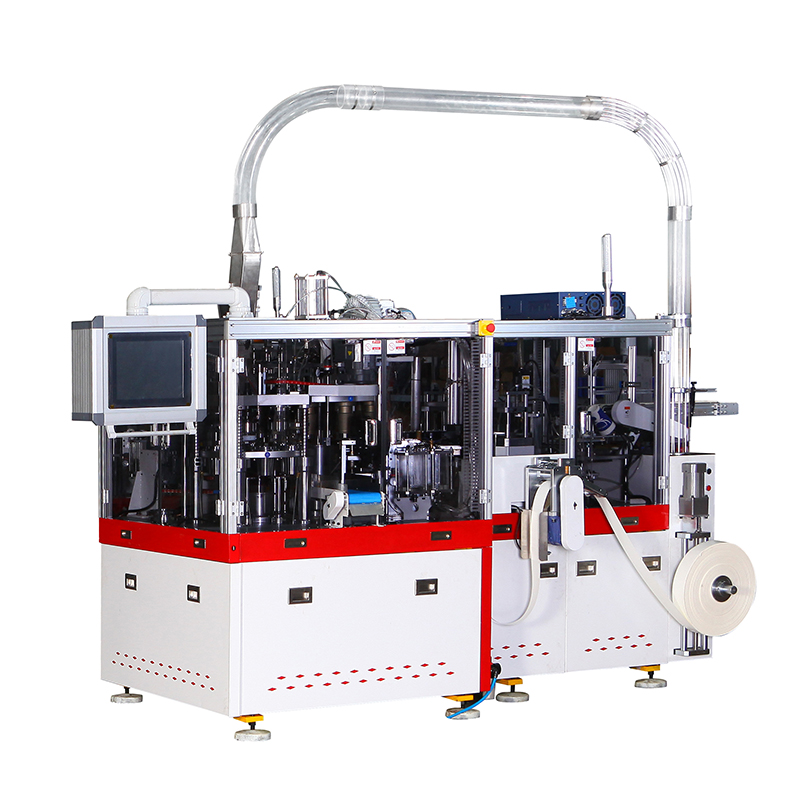

professional factory for Paper Cup Machine Repairing - SM100 paper cup sleeve machine – HQ

professional factory for Paper Cup Machine Repairing - SM100 paper cup sleeve machine – HQ Detail:

Specification of Machine

| Specification | SM100 |

| Paper cup size of manufacture | 2oz ~ 16oz |

| Production speed | 120-150 pcs/min |

| Side sealing method | Ultrasonic / Hot melt gluing |

| Sleeve sealing method | Cold gluing / Hot melt gluing |

| Rated power | 21KW |

| Air consumption (at 6kg/cm2) | 0.4 m³/min |

| Overall Dimension | L2,820mm x W1,300mm x H1,850mm |

| Machine net weight | 4,200 kg |

Finished Product Range

★ Top Diameter: 45 - 105mm

★ Bottom Diameter: 35 - 78mm

★ Total Height: maximum 137mm

★ Other sizes upon request

Competitive Advantage

❋ The feed table is a double deck design to prevent paper dust go into the main frame, which can extend the service life of the lubrication gear oil in machine frame.

❋ The mechanical transmission is mainly by gears to two longitudinal shafts. The main motor’s output is from both sides of motor shaft, therefore the force transmission is balance.

❋ The open type indexing gear (turret 10 : turret 8 arrangement to make all function more reasonable). We choose IKO (CF20) heavy load pin roller bearing for indexing gear cam follower, oil and air pressure gauges, digital transmitters are use (Japan Panasonic).

❋ Folding wings、curling are adjustable above main table, no adjustment needed inside the main frame so that the work is much easier and time saving.

❋ Electric control cabinet: The whole machine is controlled by PLC, we choose Japan Mitsubishi high-end product. All motors are independent controlled by frequency invertors, these can adapt wide range of paper character, this especially useful during bottom forming and rim rolling processes.

❋ Paper low level or paper missing and paper-jam, bottom paper missing etc., all these faults will display precisely in touch panel alarm window, which is easy and simple for operator to handle the machinery.

Huan Qiang team has been engaged in quality paper cup machinery manufacturing in China for decades. Our accumulated technologies and experience guarantee the stability and efficiency of machines at a very competitive prices.

After-sale Service

HQ philosophy is that After-sale Service is part of the complete package that we offer, and should be part of the on-going relationship after purchase. The after-sale services is provided by a skilled team of employees.

✔ Perform on-site (at customer’s facilities) installation and commissioning services;

✔ Offer breakdown maintenance support;

✔ Complete part-identification/part purchase.

✔ Optimizing productivity and production quality consultation

Get in touch today and discover how your company can benefit from HQ Machinery.

video

Product detail pictures:

Related Product Guide:

We are committed to providing easy,time-saving and money-saving one-stop purchasing service of consumer for professional factory for Paper Cup Machine Repairing - SM100 paper cup sleeve machine – HQ , The product will supply to all over the world, such as: luzern, Italy, Chicago, To win customers' confidence, Best Source has set up a strong sales and after-sales team to provide the best product and service. Best Source abides by the idea of "Grow with customer" and philosophy of "Customer-oriented" to achieve cooperation of mutual trust and benefit. Best Source will always stand ready to cooperate with you. Let's grow together!

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.